新聞中心

導(dǎo)軌絲杠的優(yōu)點(diǎn)及挑選時(shí)應(yīng)注意的問題

來源:http://m.shxcolor.com/ 日期:2019-03-22 發(fā)布人:

下面就由為您講述關(guān)于導(dǎo)軌絲杠的幾大優(yōu)點(diǎn):

Here are the experts to tell you about the advantages of the guide screw:

一自動(dòng)調(diào)心能力

First automatic alignment capability

來自圓弧溝槽的DF(45-°45)°組合,在安裝的時(shí)候,藉由鋼珠的彈性變形及接觸點(diǎn)的轉(zhuǎn)移,即使安裝面多少有些偏差,也能被線軌滑塊內(nèi)部吸收,產(chǎn)生自動(dòng)調(diào)心能力之效果而而得到高精度穩(wěn)定的平滑運(yùn)動(dòng)。

The DF (45-

第二具有互換性

The second is interchangeability

由于對(duì)生產(chǎn)制造精度嚴(yán)格管控,直線導(dǎo)軌尺寸能維持在一定的水準(zhǔn)內(nèi),且滑塊有保持器的設(shè)計(jì)以防止鋼珠脫落,因此部份系列精度具可互換性,客戶可依需要訂購導(dǎo)軌或滑塊,亦可分開儲(chǔ)存導(dǎo)軌及滑塊,以減少儲(chǔ)存空間。

Due to strict control of manufacturing accuracy, the dimension of linear guideway can be maintained at a certain level, and the slider has retainer design to prevent steel beads from falling off. Therefore, some series of accuracy can be interchangeable. Customers can order guideways or sliders as needed, and can store guideways and sliders separately to reduce storage space.

第三所有方向皆具有高剛性

Third, all directions have high rigidity

運(yùn)用四列式圓弧溝槽,配合四列鋼珠等45度之接觸角度,讓鋼珠達(dá)到理想的兩點(diǎn)接觸構(gòu)造,能承受來自上下和左右方向的負(fù)荷;在必要時(shí)更可施加預(yù)壓以提高剛性。

Using quadrilateral arc groove and 45 degree contact angle of four rows of steel beads, the steel beads can reach the ideal two-point contact structure, which can withstand loads from the upper and lower directions and from the left and right directions. When necessary, preloading can be applied to improve rigidity.

STAF直線導(dǎo)軌的挑選應(yīng)該注意什么問題呢?

What should we pay attention to when selecting STAF linear guide?

為您闡述導(dǎo)軌的應(yīng)用領(lǐng)域:

Firstly, the application fields of guideways are described for you.

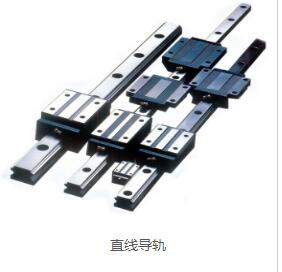

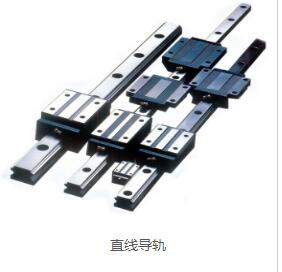

直線導(dǎo)軌主要用在自動(dòng)化機(jī)械上比較多,像德國進(jìn)口的機(jī)床,紙碗機(jī),激光焊接機(jī)等等,當(dāng)然直線導(dǎo)軌和直線軸是配套用的。

Linear guides are mainly used in automation machinery, such as machine tools imported from Germany, paper bowl machines, laser welding machines and so on. Of course, linear guides and straight axles are matched.

直線導(dǎo)軌主要是用在精度要求比較高的機(jī)械結(jié)構(gòu)上,直線導(dǎo)軌的移動(dòng)元件和固定元件之間不用中間介質(zhì),而用滾動(dòng)鋼球。因?yàn)闈L動(dòng)鋼球適應(yīng)于高速運(yùn)動(dòng)、摩擦系數(shù)小、靈敏度高,滿足運(yùn)動(dòng)部件的工作要求,如機(jī)床的刀架,拖板等。如果作用在鋼球上的作用力太大,鋼球經(jīng)受預(yù)加負(fù)荷時(shí)間過長,導(dǎo)致支架運(yùn)動(dòng)阻力增大。

Linear guides are mainly used in mechanical structures with high accuracy requirements. Rolling steel balls are used instead of intermediate between moving and fixed components of linear guides. Because rolling steel ball is suitable for high-speed movement, small friction coefficient and high sensitivity, it meets the working requirements of moving parts, such as tool holder, trailer, etc. If the force acting on the steel ball is too large, the steel ball will endure the preload for too long, which will lead to the increase of the bracket resistance.

其次是它的型號(hào)及選擇:

Secondly, it's model and choice:

(一)確定軌寬。

(1) Determining the rail width.

軌寬指滑軌的寬度。軌寬是決定其負(fù)載大小的關(guān)鍵因素之一,四排滾珠(也有部分兩排珠的)的。

The rail width refers to the width of the slide rail. Rail width is one of the key factors to determine the size of its load. Four rows of balls (some two rows of balls).

(二)確定軌長。

(2) Determining the track length.

其長度是軌的總長,不是行程。全長=有效行程+滑塊間距(2個(gè)以上滑塊)+滑塊長度×滑塊數(shù)量+兩端的行程,如果增加了防護(hù)罩,需要加上兩端防護(hù)罩的壓縮長度。需要注意的是,事先問清楚該規(guī)格導(dǎo)軌整支的較大長度,超過這個(gè)長度是需要對(duì)接使用的。多數(shù)廠家整支長度較大是4000(微軌一般是1000),有些是3000,這和廠家的加工設(shè)備有關(guān)。需要對(duì)接并且用戶想事先在機(jī)器上加工安裝孔的情況下較好提供接口圖紙。另一點(diǎn)請(qǐng)?zhí)貏e注意,導(dǎo)軌上的安裝孔孔間距是固定的,用戶在確定軌長時(shí)要注意位置,例:15的軌,長600。如果不告訴供應(yīng)商需要的端部尺寸,一般到貨的狀態(tài)是10個(gè)安裝孔,導(dǎo)軌兩端面到各自較近的安裝孔中心的距離是30、30,但也有可能是其他尺寸。各對(duì)端部尺寸的出貨規(guī)定略有差異,多數(shù)是默認(rèn)兩端相等。還有一點(diǎn),導(dǎo)軌的長度誤差,一般默認(rèn)2000以下±1~2mm,2000~4000的±2~3mm,如果用戶要求比較精確,較好在訂購合同上注明誤差值或提供圖紙。這種情況供應(yīng)商可能會(huì)收取附加加工費(fèi)。

Its length is the total length of the track, not the journey. Full length = effective travel + slider spacing (more than 2 sliders) + slider length * number of sliders + safe travel at both ends. If the protective cover is added, the compression length of the protective cover at both ends should be added. It should be noted that the maximum length of the whole guide rail of this specification should be ascertained beforehand. It is necessary to use docking if the length exceeds this length. Most manufacturers have a maximum length of 4000 (microrails are generally 1000) and some 3000, which is related to their processing equipment. It is better to provide interface drawings when docking is required and the user wants to process installation holes on the machine beforehand. Another point please pay special attention to is that the distance between the installation holes on the guide rail is fixed. Users should pay attention to the position when determining the length of the rail, for example, the length of the rail of 15 is 600. If you do not tell the supplier the required end size, the general arrival status is 10 installation holes, the distance between the two ends of the guide to the center of their nearest installation holes is 30, 30, but it may be other sizes. Each brand has slightly different delivery requirements for end sizes, most of which are the same at both ends by default. Another point is that the length error of the guide rail is generally less than 2,000 (+1~2 mm) and 2,000 (+2~3 mm) by default of the brand. If the user requests more precise, it is better to indicate the error value or provide drawings in the order contract. In this case, suppliers may charge additional processing fees.

(三)確定滑塊類型和數(shù)量。

(3) Determine the type and number of sliders.

常用的滑塊是兩種:法蘭型,方形。前者高度低一點(diǎn),但是寬一點(diǎn),安裝孔是貫穿螺紋孔,后者高一點(diǎn),窄一點(diǎn),安裝孔是螺紋盲孔。兩者均有短型、標(biāo)準(zhǔn)型和加長型之分(有的也稱為中負(fù)荷、重負(fù)荷和超重負(fù)荷),主要的區(qū)別是滑塊本體(金屬部分)長度不同,當(dāng)然安裝孔的孔間距也可能不同,多數(shù)短型滑塊只有2個(gè)安裝孔?;瑝K的數(shù)量應(yīng)由用戶通過計(jì)算確定,在此只一條:少到可以承載,多到可以安裝?;瑝K類型和數(shù)量與滑軌寬度構(gòu)成負(fù)載大小的三要素。

There are two kinds of sliders in common use: flange type and square type. The former is lower in height, but wider in width. The installation hole is through the threaded hole. The latter is higher and narrower, and the installation hole is blind hole. Both of them are short, standard and lengthened (some brands are also called medium load, heavy load and overload). The main difference is that the length of the slider body (metal part) is different. Of course, the hole spacing of the installation holes may also be different. Most of the short sliders have only two installation holes. The number of sliders should be determined by the user through calculation. Here only one item is recommended: less to be able to bear, more to be installed. The type and number of sliders and the width of slides constitute the three elements of load size.